The need to meet global challenges and the desire of expansion to new markets led to the establishment of Company MG.ANODI International Ad in November 2005. This new legal entity inherited the organisation, resources and experience of company MG. Anodi srl, former “p.i. De Stefani Luigi”.

Trademark De Stefani remains a mile-stone of the company’s thirty-year experience in the magnesium anode manufacturing business, marked by professionalism, competence and recognition.

Based in Sevlievo, district of Gabrovo in Bulgaria, MG.ANODI International Ad. has 60 employees and extends over a surface of 2,500 m2.

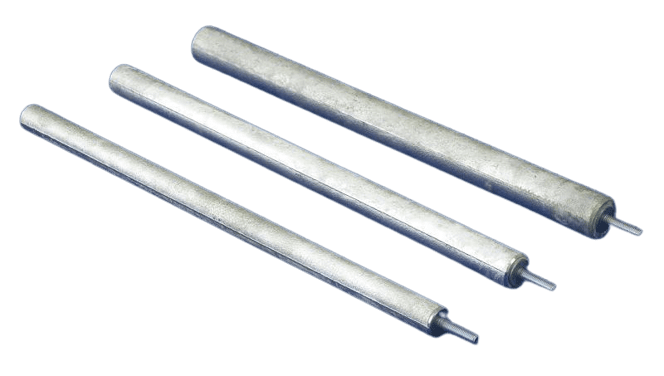

The company’s core business is the manufacturing of sacrificial anodes made of magnesium alloy for the galvanic protection of steel structures against corrosion. Over 6 million pieces are turned out every year, in a wide range of sizes, diameters and weights.

The manufacturing process involves the chill casting of a molten magnesium alloy and the contemporary insertion of a bar-shaped metal core, leaving one it ends to sticks out from the body by a few millimetres. This protruding part is used for the electric connection to the structure to be protected. Such connection may occur through threaded metal caps for a rapid positioning on the protected surface.

Over the past few years some innovations were recorded in the anode industry, the major one being the installation of a tester on the control panel of the boiler. When connected to an isolated anode the tester allows assessing the “anode’s life” through an easy manual procedure. Impressed current cathodic protection (ICCP) systems are the second major innovation which combines electronic calculation with detailed studies on the behaviour of electrochemical currents to provide outstanding anti-corrosion protection.

The company also manufactures galvanic units to protect underground metal structures, pipes and tanks from corrosion.

These are made of magnesium anodes in different sizes (most common among them 4.5 , 8. and 17 kg units), immersed in a substance with good electrolytic conductivity that can remarkably increase the supplied current. Galvanic units are provided ready –to- use.

Our products are certified by the laboratories of the University of Trento, Italy, by the Dortmund- based MPA laboratory and strictly comply with standard EN 12438. Moreover MG.ANODI International Ad. has a quality management system in place that is UNI-EN-ISO 9001:2015

Technical advice, field analyses and surveys, improvements to already existing systems and delivery of turn-key cathodic protections systems for industrial, naval and off-shore applications: this is what MG.ANODI International Ad. can offer and that makes it your ideal partner!